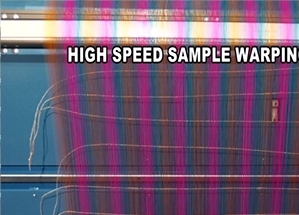

High Speed Autosampler

Model RI 6001

Highlights

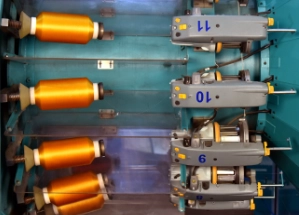

- Rotary creel that can hold 16 packages. It is easy to load all kinds of yarn packages.

- State-of-the-art yarn accumulators that allow the yarn to be laid with maximum constant tension. Speed up to 1000mpm.

- 15″ touchscreen color display HMI for data input and display of all process parameters.

- Easy-to-use, advanced and user-friendly software for data entry and display of process information by the operator.

- Advanced software automatically displays the warp pack requirement position of each color by color on the cone creel, no. Amount of warp threads, expected width, Maximum possible length, time required to complete the warp.

- The software decides the position of the package to complete the pattern in the shortest possible time to achieve maximum output.

- It also displays advanced diagnostics of all electronics and machine diagnostics to assist the maintenance engineer.

- Memory for program storage feature to prevent data re-entry.

- Separate Pre-Prep software for the preparation of subsequent programs helps to reduce machine downtime and increase productivity.

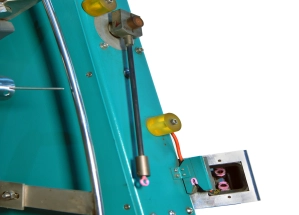

- Yarn brake detection sensors eliminate the possibility of pattern errors by detecting the yarn brake before and after the color packs of the yarn accumulator.

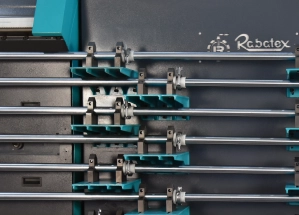

- 16 yarn needles, precisely made on the rotary, controlled by response control, precisely laying the yarn at a very high speed of up to 1000 mpm according to the placed warp pattern.

- Automatic and trouble-free, error-free selection of the required yarn for laying on the drum at very high speed.

- Synchronized yarn laying with belts and drives ensures precise laying and sliding of the warp yarn on the drum to ensure a quality warp beam.

- The automatic sequential lease function adds cross leases and cuts the lease correctly without any lease errors.

- The robustly constructed separate beam accommodates a maximum beam flange of 1100 mm and features hydraulic attachment/detachment with the aid of a pneumatic brake system. The servo-controlled beam drive ensures constant line speed in the warp, maintaining constant yarn tension.

- All Safety measures provided on all operational rotating parts include pneumatically controlled automatic rotary creel protection, warping operation protection, irradiation safety guards and all interlocked emergency buttons in different positions of the machine.

- Pneumatic beam pressing device (optional) for extra stiffness of the beam for specific warping and waxing/lubricating device (optional), with heating system, automatic oil circulation system available.